During its annual “Prime Day” celebration this Tuesday through Wednesday, Amazon has revved up its online order output to accommodate the high demand from users seeking savings during the discount window.

In Westborough at 64 Otis St., a new 200,000 square foot fulfillment center — a warehouse specializing in all aspects of the Amazon shipment process — is undergoing its first Prime Day as dozens of employees churn out tens of thousands of orders in shifts running around the clock.

Andrew Schwarz, the site lead for the facility who has been with Amazon for 10 years, said the “sub-same day” building — the only of its kind in Massachusetts — specializes in orders meant for delivery within the day of purchase bringing items from warehouse shelves to customers’ doorsteps in a range of two to five hours.

The relatively small fulfillment center, in Schwarz’s words, opened in October 2023. It averages a 35,000 package output per day, with 25% more volume expected this Tuesday and Wednesday to accommodate the heightened amount of Prime Day deliveries.

Many of the items the fulfillment center specializes in are “high velocity” items Schwarz said, such as Amazon devices like Fire TV Sticks, Ring doorbell cameras and other tech, alongside home goods, toys, cosmetics and more.

Over the last three weeks, Schwarz said there has been “a lot of lead up and preparation” to ready the site for the expected influx of order output, with increased inventory and a “constant cycle” to replenish all the items going out to meet the need coming in.

At the site, which employs just over 300 people, Schwarz said efficiency is key. Workers are largely stationary in one zone sorting and scanning items and packages while more than 200 “robotic drives” — small dolly-like wheeled robots holding item containers — autonomously navigate the warehouse floor to get these items to the right destination and do much of the legwork in the process.

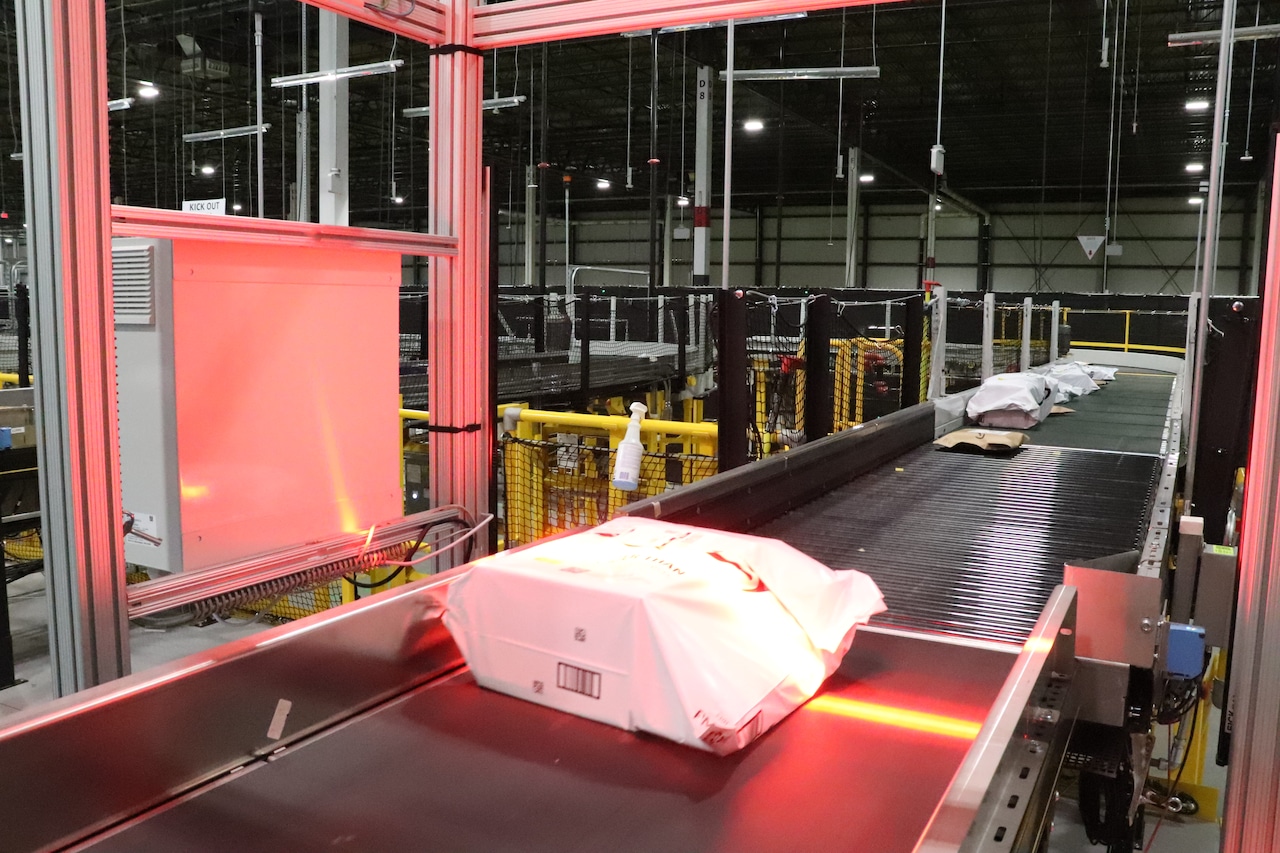

Once items are packaged, conveyor belts whisk them across the warehouse where they are stickered along the way. These stickers indicate which outgoing bin of packages they belong in.

Items bound for the same geographic route are lumped together and readied to be picked up by a driver who then disperses them to customers in a given area.

This cycle repeats itself across the course of five delivery windows, Schwarz said “breakfast, brunch, lunch, dinner and bedtime.” Each day order sorting and packaging stops during an hour window between 8 p.m. and 9 p.m. to allow for inspection and repair on the system’s mechanics, he added.

Watch a video of the buzz of activity inside Amazon’s Westborough same-day delivery fulfillment center on Prime Day below or by clicking here.